Henan Hengfu

Feed Machinery Supplier

Focus on the animal feed

machinery equipment for 27 years!+8613419860671

-

Product

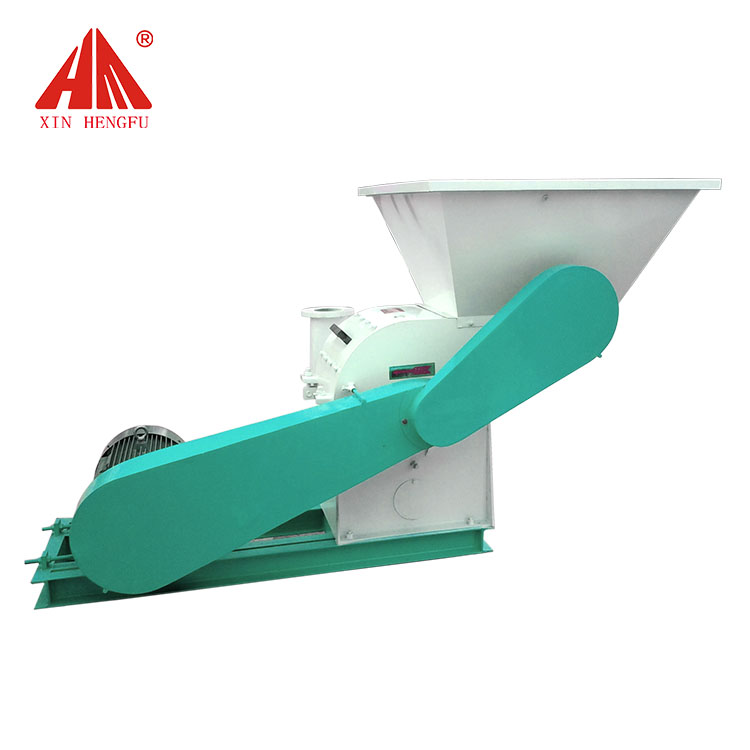

- Conveying

- TDTG bucket eleva

- TGSS Scraper conv

- Screening

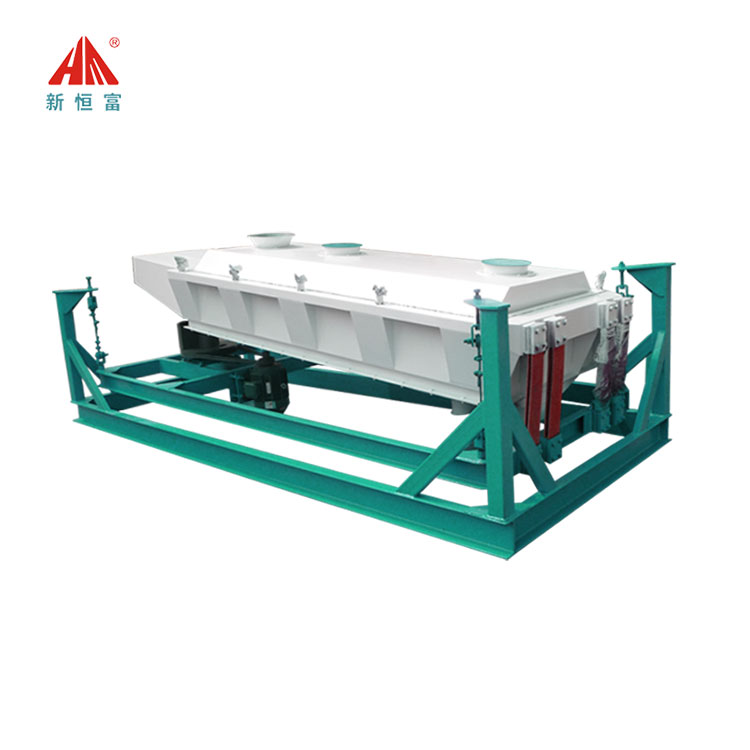

- SFJH Rotary class

- SKLN series count

-

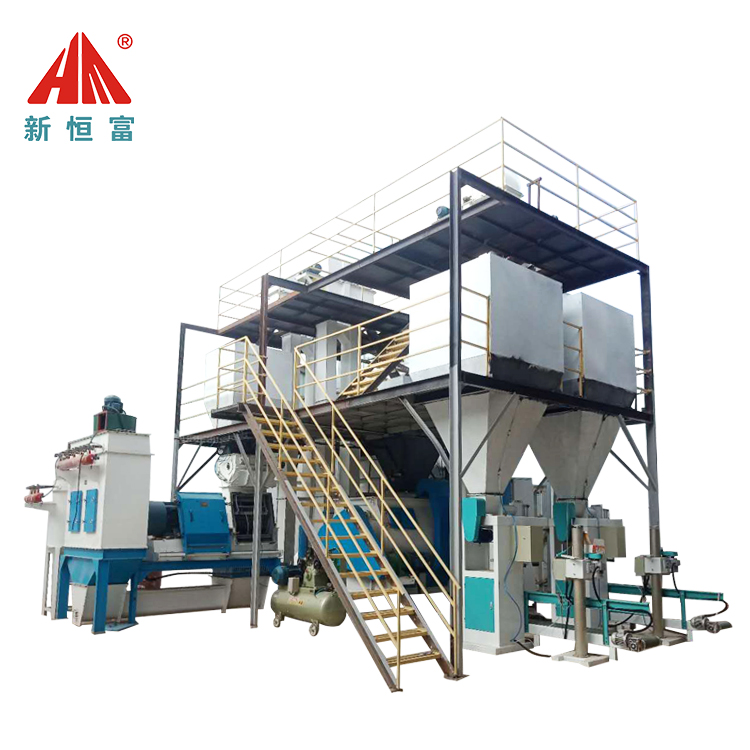

Solution

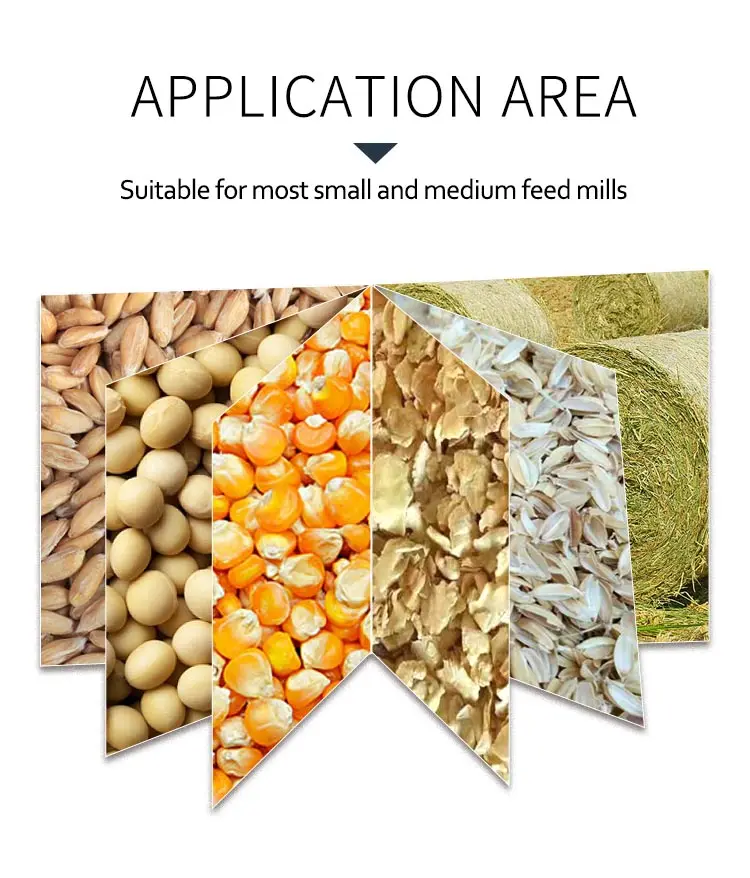

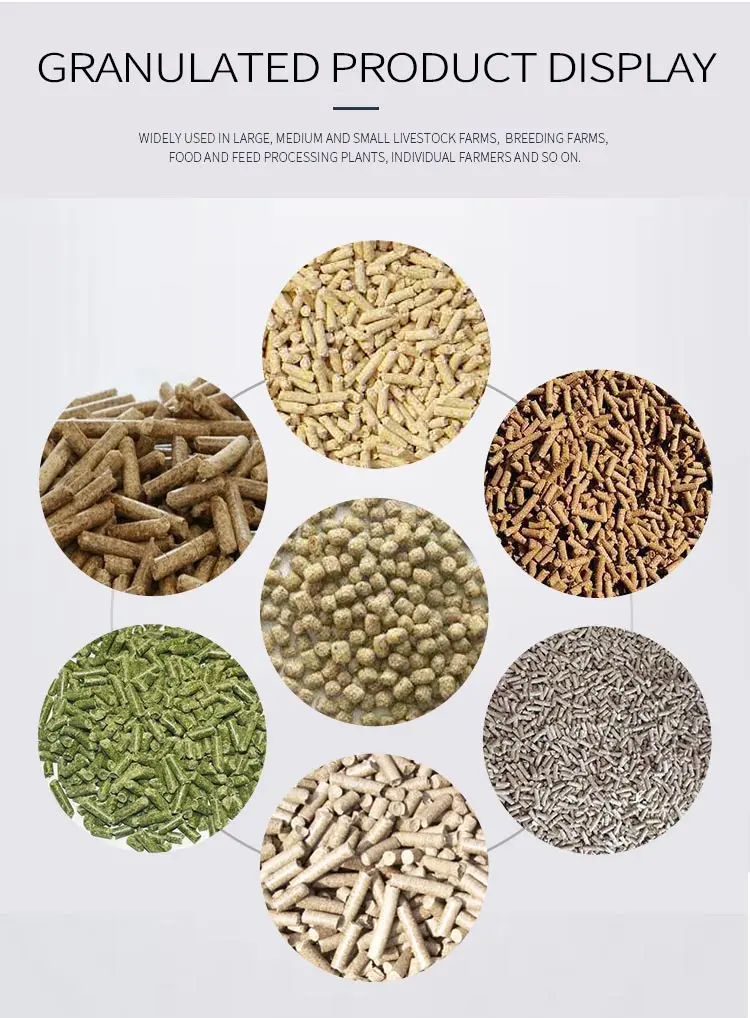

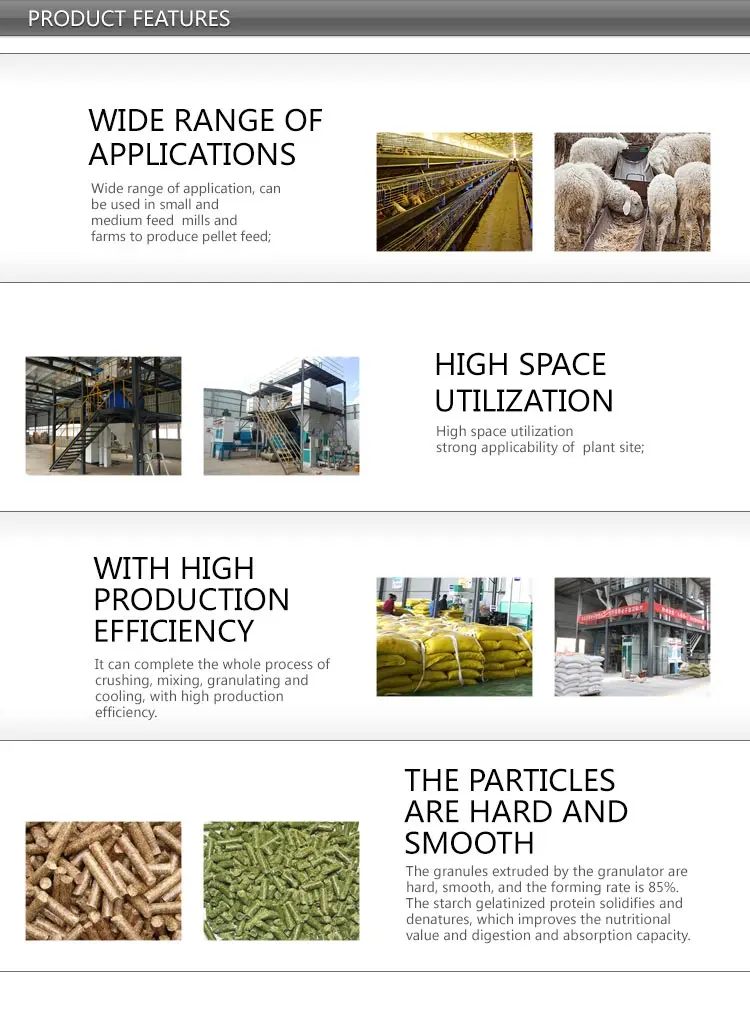

Batch material  Feed types: piglet feed, fattening pig feed, sow feedParticle diameter: 2.0~3.5mmHengfu process: 3-20 tons/hour (single production line)

Feed types: piglet feed, fattening pig feed, sow feedParticle diameter: 2.0~3.5mmHengfu process: 3-20 tons/hour (single production line)Concentrate  Main ingredients: soybean meal, peanut meal, stone powder, light calcium, soybean hull, rice bran mealHengfu process: 3-20 tons/hour (single production line)

Main ingredients: soybean meal, peanut meal, stone powder, light calcium, soybean hull, rice bran mealHengfu process: 3-20 tons/hour (single production line)Livestock  Feed types: piglet feed, fattening pig feed, sow feedParticle diameter: 2.0~3.5mmHengfu process: 3-20 tons/hour (single production line)

Feed types: piglet feed, fattening pig feed, sow feedParticle diameter: 2.0~3.5mmHengfu process: 3-20 tons/hour (single production line) - Engineering

- Case

- Service

-

Henan Hengfu